Web based training. Sign up for: RSRCH - CNF - Mask Writer Training

- Masks Only - either 0.090" or 0.250" thick

- NO wafers, pieces or other substrates without Staff assistance

The DWL 66fs is a high-resolution imaging system for exposing Cr mask plates or wafers. The DWL 66fs will accommodate media up to 6 x 6 inches. Design data can be created with any program using DXF, HPGL, Gerber, GDSII, or CIF format and is converted into a LIC format on a “CONVERT“ workstation. Design data transfer to the system is then realized via an FTP connection.

The writing is performed using a combination of raster and scanning techniques. Substrates are mechanically moved beneath the writing lens in one axis while the beam is scanned in the transverse direction. The resolution of the tool and the width of the scan are determined by the final lens. CNF has 10 mm working distance lens that produces a 2.4 um diameter spot.

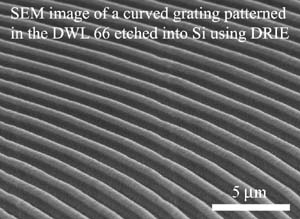

Due to the writing strategy, exposures are independent of the complexity of the patterned features. Shapes that have been traditionally difficult to pattern at the CNF-circles, curves, spirals and arcs-can be written efficiently and accurately using the DWL 66fs. This capability should be of great benefit to research in microfluidics and integrated optical devices. An example result is shown in the following figures.

The DWL 66fs also provides a comprehensive set of metrology functions including line width, overlay, stitching and pattern placement measurements. Front to backside alignment is also possible for direct write applications using a video backside alignment system.

- Write lens 10mm - 2.4um nominal spot sizes

- 6" x 6" substrates

- Solid-state Laser Source

- Input Format GDSII preferred

- Metrology and alignment system for multi-layer exposures and metrology measurements.