Tool access requirements

1. General photolithography training, online and in-person.

2. Tool-specific training, online and in-person.

Please schedule training within a week of your first anticipated use.

1. General photolithography training

For the online part of general photolithography training, use Workday Learning:

- RSRCH - CNF - General Photolithography Overview Video Training

Additionally, find required and recommended reading here:

For in-person general photolithography training, contact:

2. Tool training

For the online part of MA6-BA6 contact aligner training, use Workday Learning:

- RSRCH - CNF - SUSS MA6-BA6 Contact Aligner

For in-person training, contact the tool manager.

- 5" & 7" mask size, up to 150mm substrates size.

- Backside of the substrate must be CLEAN - No Resist on the back.

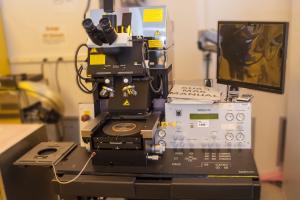

This contact aligner uses 365-436 nm light to expose wafers up to 150 mm diameter. The system features a video camera for alignment to patterns on the front or back side of the wafer. The versatile mask holder allows both round and square plates as masks, and the sample plate accommodates small and odd-shaped substrates.

- Contact lithography system

- Topside and Backside Alignment

- Flood field exposure

- Overlay accuracy to <1 um

- Substrate size up to 150mm

Alignment Mark Placement for Bottom Side Alignment (BSA):

- BSA objectives have a range of travel 24 to 95mm apart.

- The 100mm and 150mm substrate chucks have two rectangles for objectives to view the substrate.

- For 100mm Substrate Holder:

- Each rectangle is 3cm by 2cm center symmetric.

- Rectangles have diagonals of endpoints (-4.5,1), (-1.5, -1) & (4.5,1), (1.5,1)

- For 150mm Substrate Holder:

- Each rectangle is 4.5cm by 2cm, center symmetric

- Rectangles have diagonals of endpoints (-6.5,1), (-2,-1) & (6.5,1)