Tool access requirements

1. General photolithography training, online and in-person.

2. Tool-specific training, online and in-person.

Please schedule training within a week of your first anticipated use.

1. General photolithography training

For the online part of general photolithography training, use Workday Learning:

RSRCH - CNF - General Photolithography Overview Video Training

Additionally, find required and recommended reading here:

For in-person general photolithography training, contact:

2. Tool training

For the online part of ABM contact aligner training, use Workday Learning:

RSRCH - CNF - ABM Contact Aligner

For in-person training, contact the tool manager.

- 4" - 9" masks, up to 200mm wafers, up to 0.25" thick

- Back of substrate must be CLEAN - NO RESIST on back

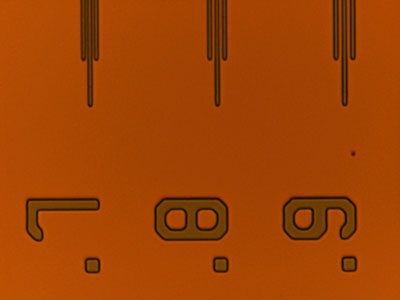

ABM's High Resolution Mask Aligner is a very versatile instrument with interchangeable light sources which allow Near-UV (405-365 nm) as well as Mid- and Deep-UV (254 nm, 220 nm) exposures in proximity (non-contact) or contact (soft & hard) modes. The exposure can cover an area 200 mm in diameter. The bottom-mount mask system accommodates masks from 4 to 9 inches square and substrates from small chips to wafers up to 200 mm. The alignment tooling system also features an air-bearing substrate-to-mask planarization system for wedge-error compensation. The printing resolution is 0.8 µm for Near-UV and 0.4 µm for Mid-UV and Deep-UV in vacuum contact mode. Exposures in Mid- and Deep-UV require quartz masks.

- Hard or Soft Contact Modes

- Any size or shape sample up to 200mm diameter and 0.250" thick.

- UV, Mid-UV, and DUV Exposure Modes

- Split-field CCD Zoom Microscope Alignment System

- Bottom-mounting Mask Holders

- Infra-red backside alignment for 2" and smaller substrates