Tool access requirements

1. General photolithography training, online and in-person.

2. Tool-specific training, online and in-person.

Please schedule training within a week of your first anticipated use.

1. General photolithography training

For the online part of general photolithography training, use Workday Learning:

RSRCH - CNF - General Photolithography Overview Video Training

Additionally, find required and recommended reading here:

For in-person general photolithography training, contact:

2. Tool training

For the online part of ASML stepper training, use Workday Learning.

Training part #1:

RSRCH - CNF - ASML Stepper Training Video

Training part #2:

RSRCH - CNF - ASML Wafer Stepper Job Programming Video Training

Additionally, find tool-specific required and recommended reading in the "Resources" section below.

For in-person training, contact the tool manager.

Training for PROLITH lithography simulation software is also available in Workday Learning:

RSRCH - CNF - PROLITH Video Training

- Standard SEMI spec wafers ONLY based on current tool configuration

- Carrier wafers MUST be approved by Photolith staff

- Back of substrate must be CLEAN - NO RESIST on back

- Mask must be CLEAN - no resist or fingerprints

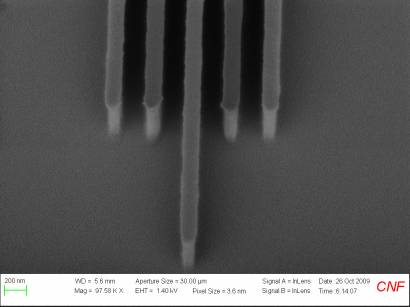

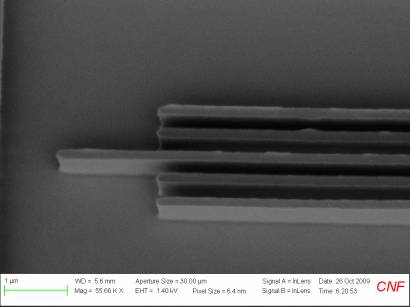

This projection printer uses a DUV (248nm) lens column (0.63 N.A.) to provide a 4:1 reduction with an exposure field size up to 22mm square. Minimum feature size is <0.20µm. The number and placement of the dies is programmable. Wafer sizes of 3" up to 200mm can be accommodated, and pieces with significant effort. Registered alignment is typically <0.045µm, even when using backside alignment. 6" x 0.250"-thick quartz masks are used.

- Step and repeat exposure system with laser-controlled stage motion

- Zeiss lens with 0.63 - 0.40 Variable N.A.

- DUV (248 nm) exposure wavelength

- Programmable Annular Illumination modes

- 22 x 22 mm field size

- 3D-Align Backside alignment